-

Control Plan

The Control Plan is the third tab on the Process Planner, and it looks like this:

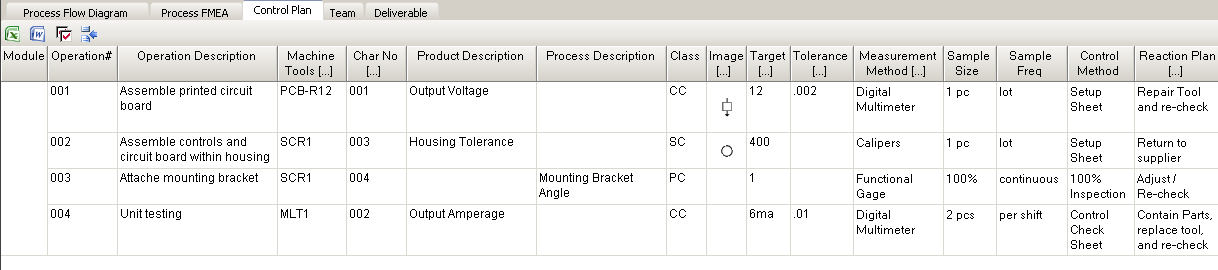

Depending on which tab the user starts, some of these properties may be already filled out. For example, if you start with the PFD, the Operation #, Description, Characteristics, Product or Process Descriptions, Target, and Tolerance would all have values. If we continue the example from PFD, our Control Plan will look like this:

Let's look at the remaining properties:

1. - the tools used to perform the operation. When the cell gains focus, a dialog comes up for entry and selection. Refer to Machine tools for a description of how this dialog behaves.

2. - the method by which the result of the operation is measured. Hitting F2 while the cell is in edit mode, brings up the Measurement Technique Catalog, from which selection can be made.

3. - number of items or parts to be measured

4. - how often the measurement will take place

5. - a brief description of how the operation will be controlled. Control Plan descriptions should reflect the planning and strategy being implemented in the manufacturing process. If elaborate control procedures are used, the field should reference the standard operation procedure (SOP).

6. - specifies what corrective actions should takes place to avoid producing bad products or operating out of control.